CMYK and Spot Colors

Posted by CBF Staff on

Products in the Creative Business Forms store are printed using one of two color processes, spot colors or CMYK. These are the two predominating color methods in the printing industry. A job utilizing spot colors will specify a number (typically 3 or fewer) of solid colors to use, each being applied in a separate run using offset printing. The CMYK model, also known as process color or "full color printing", is a comprehensive color system that creates a spectrum of colors from subtractive mixing of cyan, magenta, and yellow. It is important to understand the meanings of the terms spot colors and CMYK and to set up your artwork for the color profile you will be using.

The best practice for commercial printing regarding color profiles is to make sure the PDF document you're submitting specifies the spot colors you will be using, or is exported with the CMYK color profile if that is the process you will be using.

If your design incorporates RGB source images, working entirely in RGB and converting to CMYK at the end for the PDF export can often produce a superior result.

CMYK: the 4 Color Process

CMYK printing makes use of four ink colors--cyan, magenta, yellow, and black--to produce full color images with excellent contrast. The process by which varying shades of blue, red, orange, teal, pink, purple, and other colors are produced from cyan, magenta, and yellow is subtractive. The ink on the page filters or masks the light that reflects off of the page to create the perception of color. Cyan ink is seen by the eye as cyan because the ink absorbs red from the white light reflecting off the page. When red is removed from white light, cyan is left. The subtractive model produces color by subtracting red, blue, or green from white light.

- A printed image is made up of numerous tiny dots that are arranged and spaced so that the human eye perceives a solid color. The colors that are produced through subtractive mixing are made from carefully placing and overlapping dots so that different colors are perceived without producing visible distortions from interference (such as moiré patterns).

- The primary colors of subtractive mixing (CMY) can be combined at equal densities to produce red (magenta + yellow), blue (cyan + magenta), and green (cyan + yellow). Combining all three produces black. (This is shown in the graphic above.)

- All remaining colors are achieved by screening (or halftoning) CMY combinations. Cyan at 20% saturation can be combined with magenta at 80% saturation to make a light shade of purple. You can see in the graphic below, a screenshot from open-source program Inkscape, that adding yellow would change this color from purple to red as the saturation of yellow increases.

Halftoning is achieved by manipulating the size and spacing of the tiny dots that make up a printed image. Using a microscope, one can see these dots, and how an image is made up of overlapping dots of each of the 4 CMYK inks with different sizes and spacing.1

Key, Black, and Rich Black

The black produced by combining cyan, magenta, and yellow is deemed insufficient or unsuitable for commercial printing. These inks will not be perfectly consistent in color in different printing facilities or environments. Impurities in the ink can cause the black produced by combining the three colors to come out slightly brownish; this is a major reason why black ink is used alongside the other three colors in the CMYK process.

Black ink:

- Enhances the appearance of shaded or dark portions of an image and helps produce them more accurately and effectively, using less ink. Layering fully saturated cyan, magenta, and yellow can cause bleeding or other damage to paper, especially thinner paper stocks. Saving ink also lowers costs.

- Renders the fine details of dark text in a superior manner. Using one ink for black text instead of three prevents alignment issues and ink saturation, meaning serifs and other fine details in fonts are produced more sharply.

- Provides detail and contrast to a printed image. The black plate (if present) in offset printing serves as the key plate, providing lines and contrast--and therefore overall detail--to the image. The key plate is also used to align the remaining plates. The "K" in CMYK representing black actually stands for "key".

Combining black ink with screens of cyan, magenta, and yellow produces an even darker, more saturated black known in the print industry as rich black. This is useful for applications where darker text or graphics than standard black ink can produce is desired, but it comes with some of the same ink-coverage caveats as saturating cyan, magenta, and yellow to produce black. Thinner paper stocks cannot hold up to the heavier ink saturation (it would tear them), and bleeding can be a concern when so much ink is used and the drying process can take longer. Rich black is highly desirable for laser printing, where the dryness of toner ink eliminates these concerns.

It's best to familiarize oneself with the differences between black and rich black, and to make sure one's artwork specifies a rich black formulation in the CMYK color profile when rich black is desired.

Spot Colors

When artwork is designed for spot colors, and a print job utilizes spot colors, the colors that are specified come from a cataloged index of colors such as the Pantone Matching System, and they are produced using solid-colored inks of that exact pigment, not from screening and layering primary colors from the subtractive color model.

In the North American and European printing industries, spot colors come from the Pantone Matching System, a proprietary color system that includes over 1,800 colors developed by the Pantone corporation by combining 13 distinct pigments, as well as black. Each Pantone Color has a name or number, and this system has been standardized by Pantone so that various manufacturers (licensed and inspected by Pantone) can produce inks and dyes in Pantone colors independently of one another with consistent results. That is, a Pantone color such as Reflex Blue produced at one facility will match Reflex Blue manufactured somewhere else.

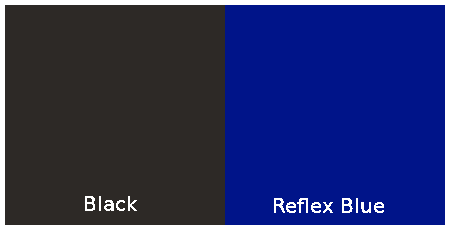

Creative Business Forms' products that use Pantone colors allow you to specify one or two PMS inks of your choosing, with the common Black and Reflex Blue options being offered at a lower cost. If you'd like to take a look at the range of Pantone colors, Pantone's website has a utility for that; and you'll see that Pantone provides a CMYK equivalent for many of these colors, whenever possible.

1 The images used in this article showing the dot patterns for halftoning and how they are perceived as solid colors were taken from the Wikipedia article "CMYK color model" as contributed by users Pbroks13 and Psiĥedelisto and are reproduced here with the assumption that with proper attribution CBF is licensed to reproduce them here. The other graphics used in this article were produced by Creative Business Forms, Inc (www.creativebusinessforms.com).